Step by step conversion. Generac 4000EXL to multi fuel.

-

Receipt and warranty registration card.

- Carefully unpack new generator so that packaging can be re-used

- Visually inspect all items to make sure nothing is damaged or missing

- Remove gas tank for easy access to top of engine. (and to keep it virgin for shipping purposes)

- Fill engine crankcase with regular oil. Crank engine for 20 seconds with the ignition switch turned Off to fill oil filter and pre-lubricate the engine.

- Check and top up oil.

- Connect temporary fuel tank with 1 gallon gasoline.

- Start generator. Let it warm up for 2 minutes.

- Check voltage and frequency at no load, check auto-idle speed.

- Plug in loads. (pair of 1750 watt heaters), check voltage & freq again.

- Run generator with varying load until fuel runs out. This is alternating loads between none, 1750 watts, 3500 watts, and idle at 15-20 minute intervals and takes about 3 hours to use up the gallon. The purpose is to properly seat the piston rings and make sure everything is tight in the entire generator.

- Drain oil into clear pan (for inspection) and change oil filter

- (added note) This is decision point for continuing. Any strange noises, abnormal voltages, or metal shavings in the oil and this genset is going back to Generac. So far, this has never happened, but my experience with other new machinery suggests that most factory defects show up during first use.

- Refill engine with full synthetic oil. I use Mobil 1 and I strongly recommend that you continue to use the same oil. If not Mobil 1, then some other full synthetic oil. It flows better cold, lubricates better, and holds up to heat better. It may cost $5.00 per quart, but this genset only takes 1 quart.

- Remove air filter assembly and stock carburetor.

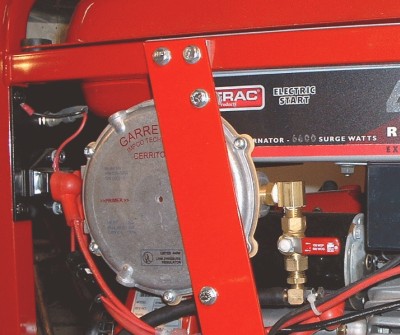

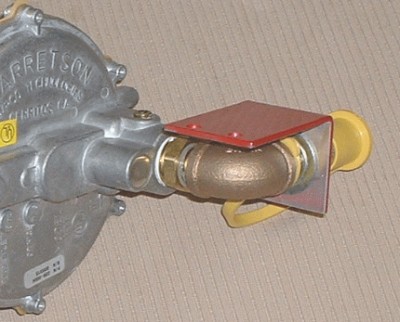

- Mount regulator assembly, quick disconnect and bracket, and run vapor fuel line from load block to carb location.

- Connect governor linkage, old gasoline line, and new vapor fuel line to new carburetor. Install carb to manifold and reinstall original air filter assembly.

- Adjust load block initially for propane. (2 turns out) (propane is all I have in my shop, so I use it for initial testing, tuning, and leak testing.

- Start and warm-up engine on propane fuel.

- Load test generator, adjust governor, set load block precisely using exhaust analyzer. Re-check voltage, frequency specs and verify smooth idle.

- Adjust load block for natural gas. (4 turns out)

- Load up generator, hose, and exhaust analyzer for trip into town.

- Repeat warm-up and tune-up using natural gas.

- Haul generator back to shop, drain all oil, install new oil filter

- Reinstall factory gas tank (that has never had gas in it).

- Repack generator in original packing. Include 1 qt Mobil 1 and a spare filter.

- ready to ship.

I've gotten email asking about the generator output capability at 120V and how Generac gets around using a "full power" switch. (which also disables all 240V outputs when set to full power setting).

Most 2 pole (3600 rpm) generators use a pair of matched windings (A & B) to provide dual voltage output. These are connected in series with the center-tap grounded to make 2 separate 120V outputs that also will suppy 240V hot to hot. Just like most house wiring.

The drawback is that only half the total output is available at either of the 120V outlets. One fix for this is a "full power" switch that disconnects the series connection between the A & B windings and hooks them both in parallel. Now you get 120V at double the current, but loose your 240V.

Some Generac generators (the Power Surge models) use a different method.

They have a third winding (B2) that is Always connected in parallel with

the A winding, doubling its current supply ability while simultaneously

providing 240V output.

Someone asked what the fuel consumption is when running on natural gas.

I tried to reply that it should be approx. 30k btu/h which works out to approx. 1 therm (ccf) for 3 hours operation. But (kicking myself) I've never actually looked at the gas meter while the generator was running.

Something I will do by tomorrow and update here.

Did it. Hooked generator up to gas meter, turned off furnace and water

heater so gen was only gas load. Plugged in 2 electric heaters and a

hair dryer (on low). Enough to make the genny grunt a little.

It used 3.8 cu ft in six minutes. ->38 cu ft per hour.

So 1 therm or ccf would be consumed in just over 2.5 hours.

That means 40 cents per hour at full load and current nat gas prices.

>On 02/11/05 *wildwood (or swood) asked:

>Dear serley,

>

>hi again, I am building a small methane digestor that I would use to fuel

>this generator. Do you have any experience in that area? I will have

>scrubbed gas (1000 btu/ cf) and plan to run the generator a couple

>hours / day. is the life expectancy truly about 3000 hours?

>thanks again Woody

>

Sounds like an interesting project. Have you made a working digester before?

Sorry, I don't have any personal experience with them. Natural gas is mostly methane, so a generator will run just fine on methane. It needs to be fairly pure, and under enough pressure to flow around .5 - 1 cu ft per minute into the regulator. (.3-.5 psi)

If your methane is testing out at 1000 btu/cf it sounds like it is pure enough.

Engine life is going to be much more dependant on proper maintainance than what kind of fuel you burn. (within reason). Natural gas and propane are supposed to burn cleaner than gasoline.

Change the oil and filter regularly, check air filter. Take it easy on the loads, make sure genset is clean and well ventilated. Let it warm up before adding load, let it cool down after use. Should last for years, even with your proposed 2 hours per day use.

I'd be interested to hear more as your project progresses. If you don't want to fix your email address on eBay, you're still welcome to contact me by email to serley-at-yahoo-dot-com or steve.erley-at-verizon-dot-net.

Steve