Chapter 0

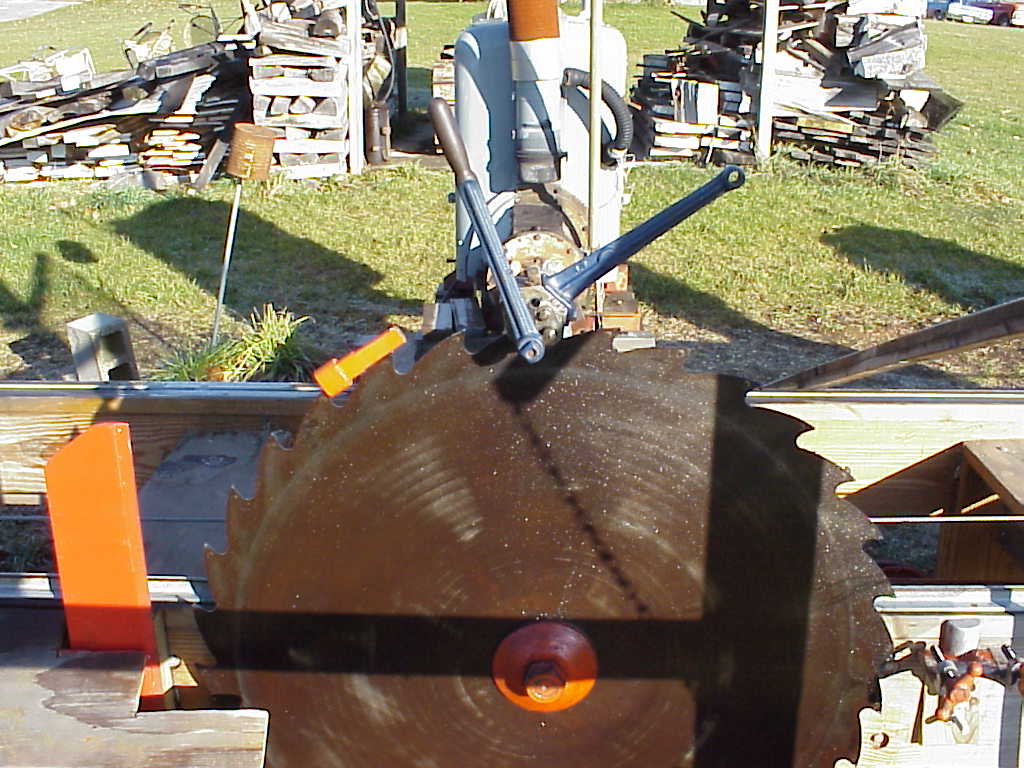

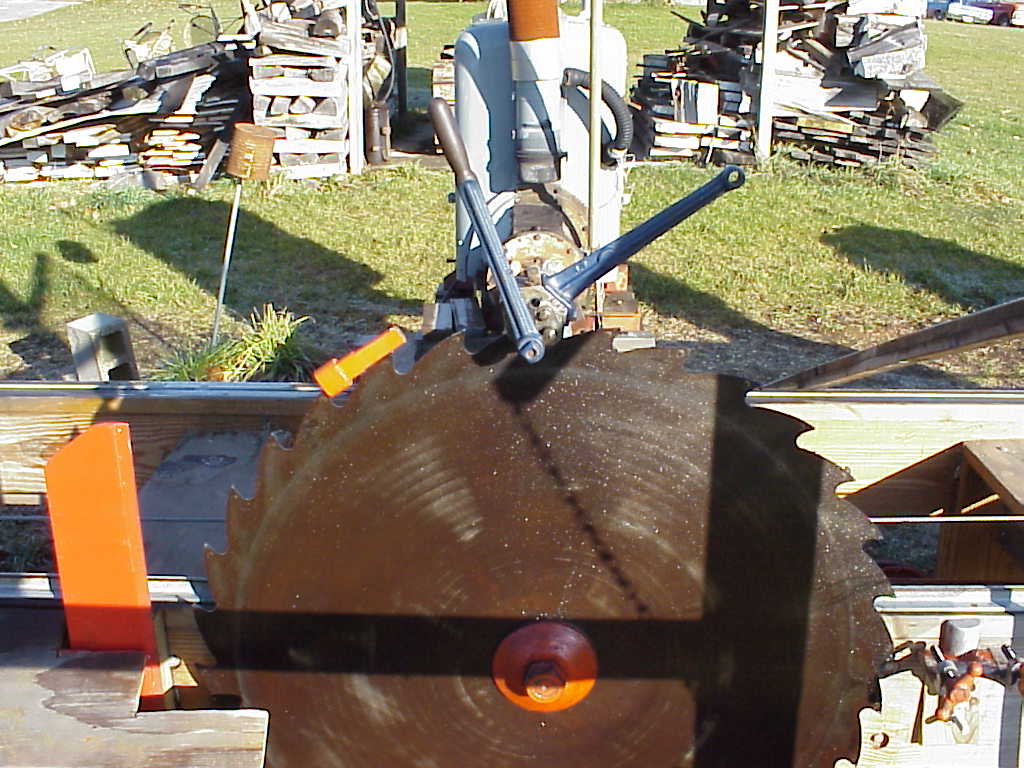

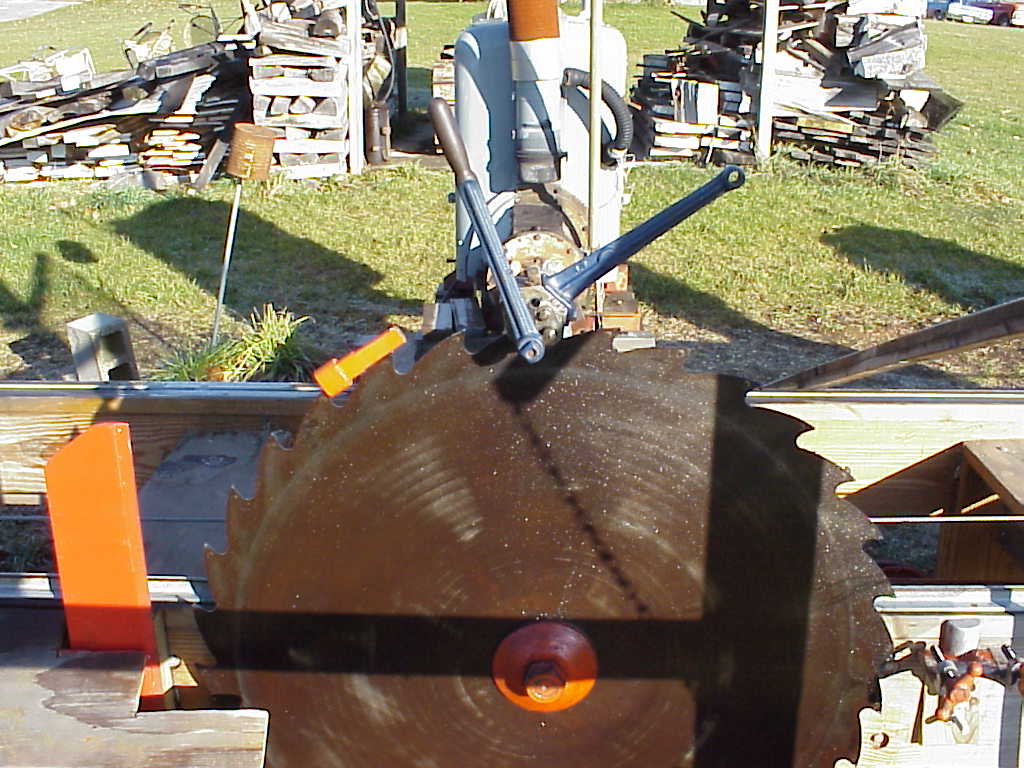

Saw mill blade swedging.

Page 1

Saw mill blade swedging is a process that gives clear'ance between the blade and the wood to stop heating of the blade. Swedging does not remove metal from the blade, the swedge pushes metal back and creates a larger tooth top which clears the wood. Before swedging check that the blade is round by clamping a stick to the mill and rotating the blade, correct any high teeth. Two types of swedges are pictured in the images the red one to the left is a hammer type and the one to the right is a roller type actuated by a lever. When using both swedges lock the blade with the saw guides and wedges. The hammer swedge cavity is set firmly on the tooth and hit with a hammer try to keep a uniform size when forming the tooth tip. The lever swedge is set on the tooth and locked to the tooth and with the handle held firmly pull the lever the roller will start to form the tooth upset repeat until the tooth has a good upset. Once the teeth are swedged, light filing on the front face of the tooth is all that is needed to touch up the blade. Tooth shape must be maintained by gumming or filing, make a pattern of metal, of the tooth shape if the cavity of the tooth becomes too small there will not be room for saw dust and the blade will heat and it will take more power to saw. The reason to avoid heating is that if the blade heats it will start to wobble as the rim expands and your mill will go out of control and you will have to stop sawing. If the teeth are in good shape, properly sharpened and hammered to the hand of your mill and still heats and wobbles the rim may have to be hammered by hammering lightly around the rim to loosen the blade edge. Try this yourself but if you still have trouble have an experienced man do this.