Chapter 0

Jointing table saw blades.

Page 3

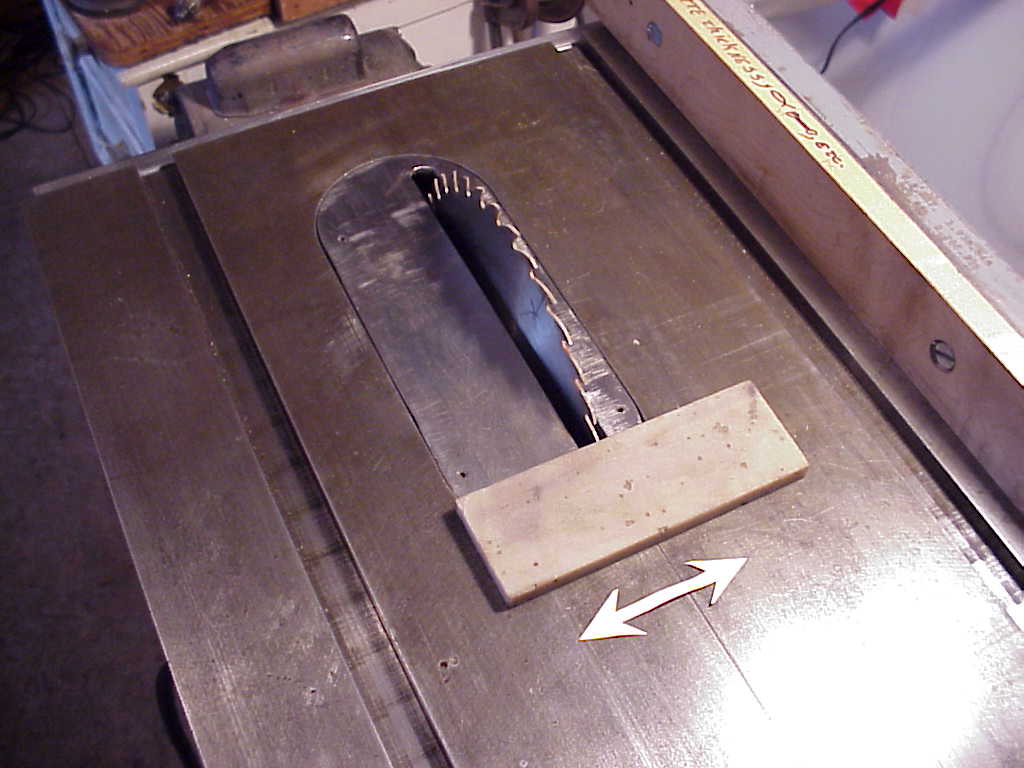

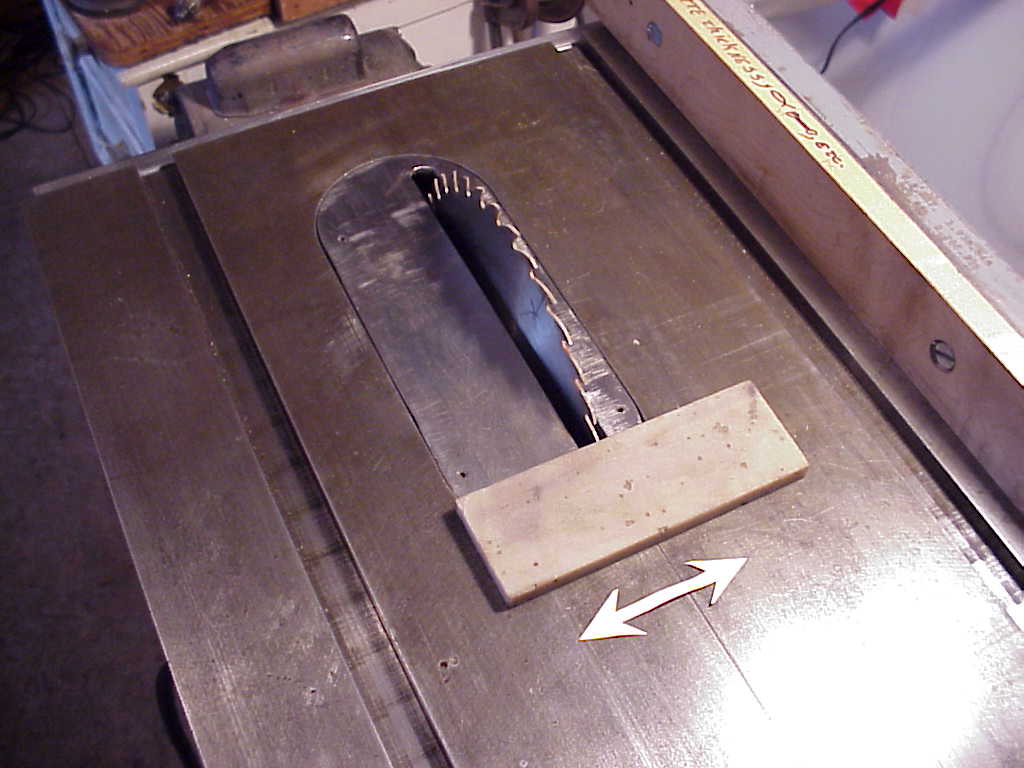

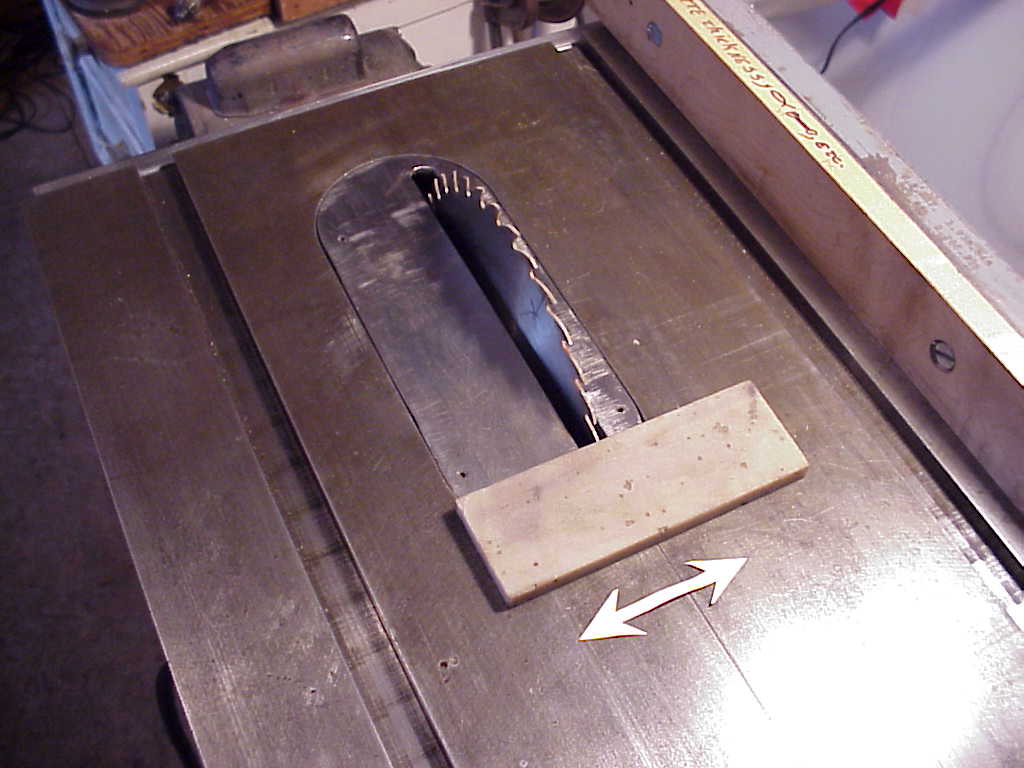

- Jointing table saw blades must be done to have a round blade with all the teeth working and sharing the work. Use an old whetstone as in the image and with the saw running gently touch the blade and move the stone laterally as shown by the double arrow in the image. On very thin blades .025, as the one used for cutting fret slots, veneer, bone etc. if the blade is out of round and only a few teeth are cutting heating will occur and the edge will roll over and the blade will wobble ,improper set can also cause this. If the blade is round and the teeth are set and filed properly and the edge still rolls over, hammer the edge lightly close to the gullets of the teeth with a small hammer on an iron block or anvil. This hammering relaxes the rim, if the rim is too loose tighten by hammering near the shaft arbor. Thin kerfed blades from suppliers often need correcting and hard materials like bone will require blade tuning.