Chapter 7

Assembly of the rosette

Page 15

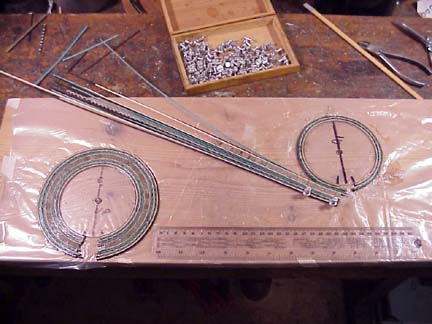

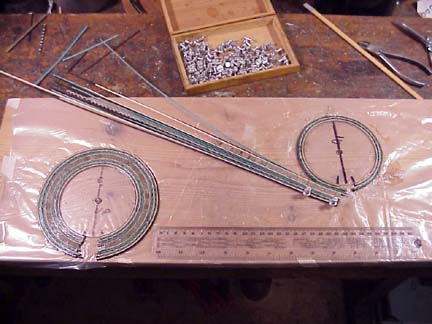

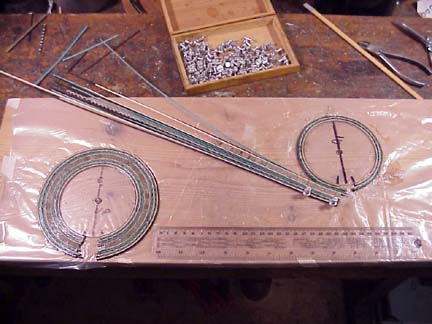

Assembly of the rosette is enjoyable because after all the planning and construction of the various parts, that which you conceived is becoming a reality. Wax heavily a piece of softwood which will be your assembly board cedar or soft pine is good and put plastic sheet or waxed paper on it. Next make your rosette interior dimension disk of 2.5mm plexiglass or wood heavily waxed wood, make it larger than the size of your 85mm sound hole the margin is that which pleases you. Put a wood screw in the middle for mounting to the work board. Get some pins as in the image these are for holding the various elements of the rosette during assembly. Try to get the pins with the large top as they will be easier on your thumb. Heat up your glue and thin it so it runs easily off the end of your brush. Have a hot plate with hot water and an extra jar of glue heated. In case you should run out of glue or spill your glue pot, and a rag wet with water for cleaning as you proceed. In the image on the right are strips, herringbone and tiles in proper order. Set up the order for your rosette on a bench away from where you are working. Go to the rosette pieces and take three of the starting strips and having everything ready dip the ends in glue and start at the lower left or right, whatever is easiest for you. Proceed glueing and pinning in about an hour start another layer. When glueing herring bone or other laminates to be bent use plenty of glue as the glue will soften the design and avoid damage. When bending herringbone put two strips on the outside this will also avoid damage. Tiles will have to be set close by, a piece of wood with groves for the loose tiles works well. Place the tiles with two outer strips and go around. Keep cleaning the excess glue as glue build up will be in the way of the next layer. Proceed in this manner until done.