Sub-Aqueous Sand Cap Surcharge Placement Sub-aqueous

capping is performed on environmental remediation sites to isolate contaminated sediments from the

surface environment. This construction method can also be employed on projects

involving construction on submerged soft sediments to build up a firm and uniform underwater work surface. Sub-aqueous caps are essentially "sprinkled" into place underwater with minimal disturbance to the underlying soft sediments and can be placed evenly from floating platforms either

hydraulically or mechanically. Mr. Wells's QA/QC system has been used with the

two hydraulic placement barges, as pictured below. Sand is mixed with water

and pumped to a placement barge where baffling and screening controls the sand's

outflow. The system could also be used with a mechanical placement

system, provided

that an electronic scale can monitor the flow of capping material. In 2004, on behalf of environmental contractor

Envirocon,

Tom was asked to propose a QA/QC system to help guide and document a sub-aqueous

sand capping operation at the

St. Louis River Interlake Duluth Tar Superfund

site in Duluth, Minnesota. Envirocon was awarded the general construction

contract for placing a sand surcharge on impacted sediments in Stryker Bay,

Minnesota in 2006. Tom designed, built, implemented and operated the

original sub-aqueous capping QA/QC system that year. The 2006 environmental construction task placed 58,755 tons of

man-made sand under water on 11 acres of tar-contaminated sediments. The sand

was pumped 2,600 feet from shore to a placement barge operating in shallow

water. Once the sub-aqueous cap was completed, additional sand was placed

temporarily using conventional land-based methods to compress the contaminated

sediments. Starting in 2009, that temporary sand layer was removed to

recreate the original bathemetry. Some of the equipment and programming involved is discussed

below. Note: The sub-aqueous capping system was also utilized in 2009 and

2010 to help guide and document capping in Slip 6 near Stryker Bay, MN.

(Slip 6 has become the CAD; the Contained Aquatic Disposal area.) The main

QA/QC program was modified in 2009 primarily to deal with a different conveyor belt

and more importantly, a different brand belt scale (with a similar but different

integrator / controller).

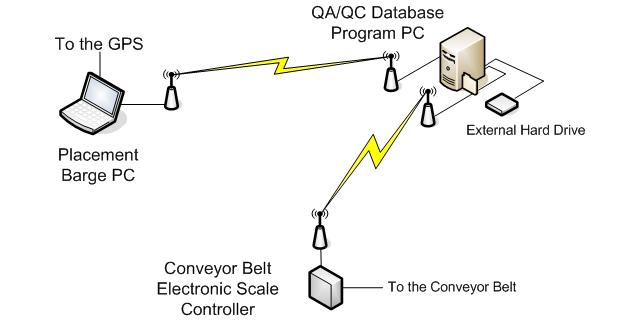

As shown by the connectivity diagram below, the QA/QC system utilizes two wireless links: one connects the QA/QC PC

to the placement barge; the other connects the QA/QC PC to the stationary

conveyor belt scale controller / integrator. The sand feed rate is

obtained from the conveyor belt scale and used to calculate the target placement

velocity for the desired thickness. This target velocity can be

transmitted for visual display to a PC on the placement barge or elsewhere. Both the scale and GPS data streams

are stored in a multi-user database on the QA/QC PC by the main "Cap

QC" program discussed below. Microsoft®

(MS)

Excel and Visio were used to generate tabular and graphical reports from the

shared MS Access database. (See REPORTING below.)

The two-way wireless link to the placement barge was also used to simultaneously

track the barge's location in real-time at the

QA/QC PC Trailer. (See REAL-TIME TRACKING

below.)

In 2006 the GPS data was converted to state plain coordinates by HyPack, a

hydrographic surveying program, running on the Placement Barge PC. (The

wireless link from the Placement Barge to the QA/QC PC was a two-way Ethernet

based link in 2006.) In 2009 and 2010, the GPS data was converted to state

plain coordinates by CableVision, a commercial dredging package, running on an

additional PC in the

QA/QC trailer. (The wireless link from the GPS to the CableVision PC was a

one-way RS-232 based link in 2009 and 2010.) The CableVision PC was also

used for real-time placement barge tracking.

In both cases, the processed GPS data was transmitted via a Local Area Network

in the QA/QC trailer to the main QC program for storage in a MS Access based

multi-user database.

In 2006 a Belt-Way Scales, Inc. brand conveyor belt scale was used with their

standard controller / integrator. In 2009 & 2010 a

ConveyWeigh, LLC

brand conveyor belt scale was used with their standard controller / integrator on a

different conveyor. Both controllers utilize an RS-232 serial interfaces

for communication with 3rd party systems such as the Sub-Aqueous Capping QA/QC

System. The Belt-Way controller can be set to output scale data every minute or

scale data output can be requested by transmitting a code to the controller.

The ConveyWeigh controller simply outputs scale data approximately every second.

During all three sub-aqueous capping construction seasons, both scale and GPS

data was captured approximately every 9-10 seconds. Consequently, the

capping QA/QC program was programmed to request a reading from the Belt-Way

controller every 9 seconds and allow 1 second for the response. The

communication approach with the ConveyWeigh controller is to simply look for

data every 9 seconds and if the data is incomprehensible due to the lack of data

flow control, then the next data set would be captured one second later. During capping operations, the main Cap QC program runs

continuously on the QA/QC PC capturing and storing two data streams; placement

barge location and capping material conveyor belt scale readings. Both raw

text data streams are shown on the main program form below (including some

unprintable ASCII characters as vertical bars). The following screen shot was captured 8/27/2010

at 10:09:32.781 according to the GPS data stream. According to the Scale

Input Stream, the scale had totaled 62,712.656 tons of capping material at this

point. The 2010 version of the Cap QC program calculates the actual

placement barge speed as well as the calculated target velocity based on the

capping material feed rate. (The actual velocity calculation and display

was added because the GPS used in 2009 & 2010 did not supply the actual

velocity within the GPS data stream.) The target velocity is the placement

speed that will produce the desired lift thickness based on the feed rate,

placement width and the capping material unit weight.

The target velocity can also be transmitted to the placement

barge for display on a PC running the QC Monitor program (and other programs

such as HyPack, a hydrographic mapping program). An example of the main QC

Monitor form and the QC Monitor Details form are shown below. The QC

Monitor program displays the target velocity after the use specified "Current

Soil Delay". In the 2006 example shown, target velocities are calculated every

10 seconds and displayed after a 60 second delay to account for the travel time

from the scale to the placement barge. Hence the 11:57:09 target velocity

was received last but the 11:56:09 target velocity is displayed to the operator

on the main QC Monitor form.

Computerized QA/QC System

INTRODUCTION

The 2006

Placement Barge Operating in Stryker

Bay, Duluth, MN.

MCM Marine, Inc. was the Marine Contractor.

The 2009 / 2010

Placement Barge Operating in Slip

6, Duluth, MN.

MARINE TECH, LLC was the Marine Contractor.

Some of the

sand placed on site. Reddish sand was used too.

The partially hidden 60 ton off-road truck looks tiny compared to the pile.

SYSTEM LOGIC

GPS DATA PROCESSING

CONVEYOR BELT SCALES

QC PROGRAMS

|

|

The main QC program stores the GPS and scale data in a MS Access database that can be accessed by multiple PCs simultaneously even while new data is being added to the database file. This multi-user capability allowed for the creation of a MS Visio based real-time placement barge tracking system. The following partial screen shot shows the system in action drawing the placement barge's path in the CAD on August 28th, 2010. The red placement barge tracks show how the crossed out area was avoided (once the cables were marked).

![]()

Daily sand placement reports were generated during each 2006, 2009 & 2010 construction season. Microsoft Visio was also used to produce, weekly reports, tracking reports, and lift reports based on the captured data. An example lift summary report is shown below from 2006.