|

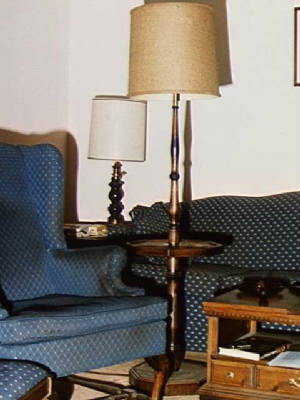

Before I got my full sized Delta lathe, I had inherited an rather old, small

model (Dunlap brand from Sears). With an 8" swing and 26" long bed, its capacities limited projects. Thus the pole was turned

in two sections with planned joining by a dowel. Brass plumbing fixures were modified to make a hollow tail piece for boring

the pole lengths. After making the octagonal base, I decided to incorporate an octagonal tray.

25 years of use has given it a nice patina.

The corner of the coffee table visible is the one I mentioned in the photo of the end table.

The top measures 21" w x 32" long when closed. The two leaves open book-like to 64". About two years after construction, we

heard a loud crack from the living room. Eventually, it was traced to the splitting of an end panel. Poor design (not mine,

it was a kit, remember) used glued on cleats to support the top. It was my first experience with wood movement in furniture

construction - never forgotten.

Continuing with the Colonial theme, I wanted a Queen Ann piece with cabriole

legs. Still a bit timid of my ability, I could not take on a secretary, highboy, nor even a lowboy chest. No living room recliners

and a hassock showing considerable signs of wear pointed to a footstool as an approachable project.

The wood is cherry and the uphostelry was chosen to match a wing chair. Thankfully, I prepared

six blanks for the legs. Learning to use a spokeshave, rasps, and the judicious use of sandpaper was a true learning experience.

This dining area valence has a couple of interesting features. Although it

appears to have been finished with three different stains, that is not the case. The single stain of Golden Oak is shaded

by the cut surfaces. The crown molding is a rift cut, the dentil is quarter-sawn, and the frieze is flat sawn.

This corner cabinet is a commercial product. Newly moved into our Carolina

home, my wife would never be patient enough for me to build one. The crown molding was obviously cut with custom knives. I

wanted to match the valence cove to this piece.

The cove is assymetric: 1 ½ wd x ¼ dp with the apex offset

3/8 from center. I was familiar with cutting simple coves on a tablesaw and somewhere I had come across an article about tilting

the blade when cutting a cove. I could not locate the information so I started from scratch with a Works spreadsheet. This

was in 1997, since then, as a lifetime subscriber to Fine WoodWorking magazine, I can refer you to Issue 168, February 2004,

page 68 - Cutting Coves on the Tablesaw, by Stuart Sabol. This is an excellent article with good illustrations. To get to

their Web presence, simply Google fww.

Success with the Dining Area valence pointed to one for the living room.

Oak is for the kitchen/dining, cherry for the living room. No need for asymmetric coves, this would be much simpler to fabricate.

Almost every project seems to have a story - keeps life interesting and humbles

me. I had recently purchased a sliding compound miter saw. Accompanying instructions told how to cut crown moulding flat on

the table with appropriate angle settings. No fool I, practice on scrap would point the way.

After proving to myself that the system worked, I was ready to cut the return ends on the

real thing. Remember the tool and I are new to each other. instead of a left and right miter - two left miters! Start over?

No way. Solution: cut in center and add a shell carving. A serendipitous improvement to an otherwise plain decoration. The

addition of four low wattage frosted bulbs on a dimmer provides indirect lighting, good for TV viewing.

|