Bret's Cobra - Page 12 (Done!)

Final Assembly (Summer/Fall 2012)

With the

car back with paint, it was still surprising how much work there was

left to get everything back in place. Especially considering how

careful one has to be now that it is painted. Every installation

took 3 times as long due to the process of taping and placing

protective cloths anywhere near the work space. One of the first

things to install was the door straps. These prevent the door

from opening too far and were a requirement now that there was paint on

the car otherwise the doors will swing wide enough to ding the perfect

paint job.

There

are many other deatils which were not interesting enough for pictures.

Things like the roll bars, gas cap and windshield wipers.

These were thigns taht were all sorted out before paint but were

painstaking to install with a painted body because of how careful you

need to be with the fany paint job.

Snags in the Progress

There

were a couple of snags in the progress and excitement of getting the

car back from paint. The first thing that showed up was that they

had lost the spacers that fit between the hood hinge plate and the

bracket that I bonded to the hood. This meant that as the

tightened the bolts it pulled the bracket away from the hood.

After consulting with SRP (Street Rod Painter) via email and

other research, I decided to pull the hood and hinge pieces completely

off the car, rebuild the precise spacers, and then use marine epoxy to

bond the bracket back to the hood. This was a very difficult

process but was well worth the time and I think turned out very nice.

The epoxy seems to be holding very well and after some touch up

paint it all seems to be nearly invisible. Unfortunately a poorly

timed hard drive crash caused me to lose my pictures of the process,

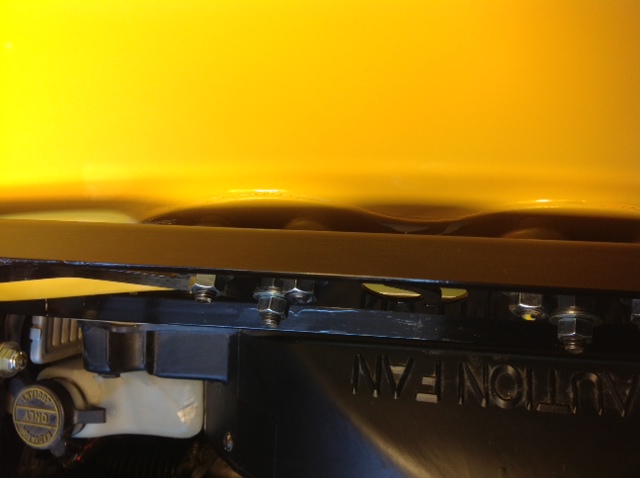

but here's a good one showing the end result. The black

horizontal bar is the hinge plate. The curved part in the shadow

is the bracket that was bonded to the hood and then pulled away (the

spacers fit between these two to match thr curvature of the hood).

If you look very closely, at the edge of the bracket (curvey part

in the shadows) there is a faint crack where the paint separated when

it was unbonded. But being behind the hood hinge plate it's very

difficult to notice :-).

Snag part 2

The

second snag was that the paint was so fresh that after several

open/close cycles with the trunk one of the hinges ended up peeling the

paint away from the body. The curve of the body/trunk at the

point of the hinges makes it so that the hinges twist a little as the

trunk lid moves. With the fresh paint this caused the peeling.

After more consultation with SRP I was able to address this with

3 steps: 1) stick the paint back down using clear fingernail

polish and touch up paint, 2) limit the height to which the lid opens,

and 3) use some slick plastic as a "washer" or gasket to allow the

hinges to twist without scartching or peeling the paint. I found

some clear plastic take-out containers that were very slick and just

the right thickness and cut out my own gasket material. Here are

a couple of pictures of the problem and the end result after the

repair. It has held up for months now so I think it's in great

shape and nearly invisible.

After

getting the snags fixed up I was able to take it out for spin and snap

a couple pictures of the "not quite" done car in the fall colors.

Louvers

After

seeing how nice everything looked with the fresh paint job I had to

replace some of the exterior trim. The windshield bezels that

came with the original kit were just aluminum and I had polished them

as best I could but they looked wrong next to the fresh paint. So

I ordered the new bezels that factory five includes with their new kits

and was very happy I did (but it did take another afternoon as I had to

remove and reinstall the windshield). The bended aluminum louvers

filled me with the same feeling so I splurged and got a much nicer set

from finish line. Then the question was how to mount them.

SRP to the rescue again. His suggestion was to use the

included angle brackets but to make it removable with velcro. As

velcro can sometimes come loose with heat, the plan was to provide a

permanent "shelf" so it is not fighting gravity. Marine Epoxy

holds the bottom "shelf" in place and the louver sets on top of it with

velcro holding it in place. The top angle bracket is riveted to

the louver and then velcro is used to hold it to the side of the

fender. Here's the prepped pieces and the finshied result.

Interior Trim (Winter 2012/13)

The

kit came with an e-brake boot, but no trim ring and a shifter trim ring

but no boot. My wife kindly made a shifter boot out of the door

pocket material (see below) but I still needed something for the

e-brake ring. I searched online in hopes of finding something

suitable, but all that I could find were much smaller ones made for

after-market e-brake handles rather than the beefy one from the mustang

that I had used. I considered changing the e-brake handle to one

of the aftermarket ones but that was a lot of work too so instead I

fabricated my own trim ring out of aluminum. It is very difficult

to get something precise and polished so that it looks good, but with

tons of work and care I came out with something that looks OK even next

to the chrome plated one for the shifter. Here's the end result

and I think it turned out nice.

The

kit included some pretty sad black trim to fit over the door sills and

cover the section between the carpeted interior and the body. But

after everythign else looked so nice it seemed like a shame to put on

such a poor looking cover. I've also heard that it pops off if

you brush it with your feet getting in or out. Not a good

solution. So someone on the forum sells some shapred angle

aluminum that fits perfectly and screws into place. With some

care and plenty of painters tape for the trial fits I was able to get

the door trim pieces installed and it really gives the interior a

finished look.

The

next piece to add the final finished feel to the interrior were the

door panels. The kit came with material that matched the dash

that was for installing as pockets on the doors. But another

forum member designed and manufactures very nice door planes which fit

perfectly and really provide a "factory" look to the interior.

DONE!

I'm

sure there will always be upgrades and work to do. I can

already list many things (need to repaint the side pipes, center the

steering,...). But I believe this qualifies as "done" and I now

consider all the others as upgrads or maintenance. Here are a

bunch of pictures I snapped while I was out for my first "it's done"

drive.

I'm sure there will be more adventures and great pictures from fun drives in the future.

Go to Page

1

Go to Page

2

Go to Page

3

Go to Page

4 Go to Page

5

Go to Page 6

Go to Page 7

Go to Page

8

Go to Page 9

Go to Page 10

Go to Page 11