|

Once I had tackled the "small stuff" it was on to the wings. This meant the Flaps and Ailerons were

next on the list. I had purchased the preformed kit from Sonex so the hardest part was done for me. All I needed

to do was male the ribs and cut the sheet stock to size. I would strongly suggest that you do not use a form block to

make the ribs for these parts. You will be left with ribs that look like banana's. Lay out the flat pattern and

use the bending brake. You will get parts that look nicer and will fit better. When it comes time to do the actual

wing ribs you will have to use form blocks (if you're plans building).

A flap rib that was formed using a forming block. You will need to flute them in order to get them

straight. Here I have marked in red pen the rivet locations.

CONTRUCTION TIP!

Take a fine tip Sharpie and draw a line down the center of each rib flange. You will use this later

to align the ribs when they are inserted into the skins.

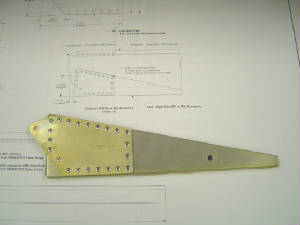

Flap Drive Rib. Keeping with my philosophy of protecting all parts that will be enclosed I have chem

coated this part.

Fitting all of the flap parts together.

CONSTRUCTION TIP!

Do not draw your cut line on the protective plastic. If you use a Dremel with a cutting wheel (as

I suggest you do) the plastic will melt and your line will move. Use a cheep soldering iron to melt/cut away the plastic in

the area's that you are going to cut.

|